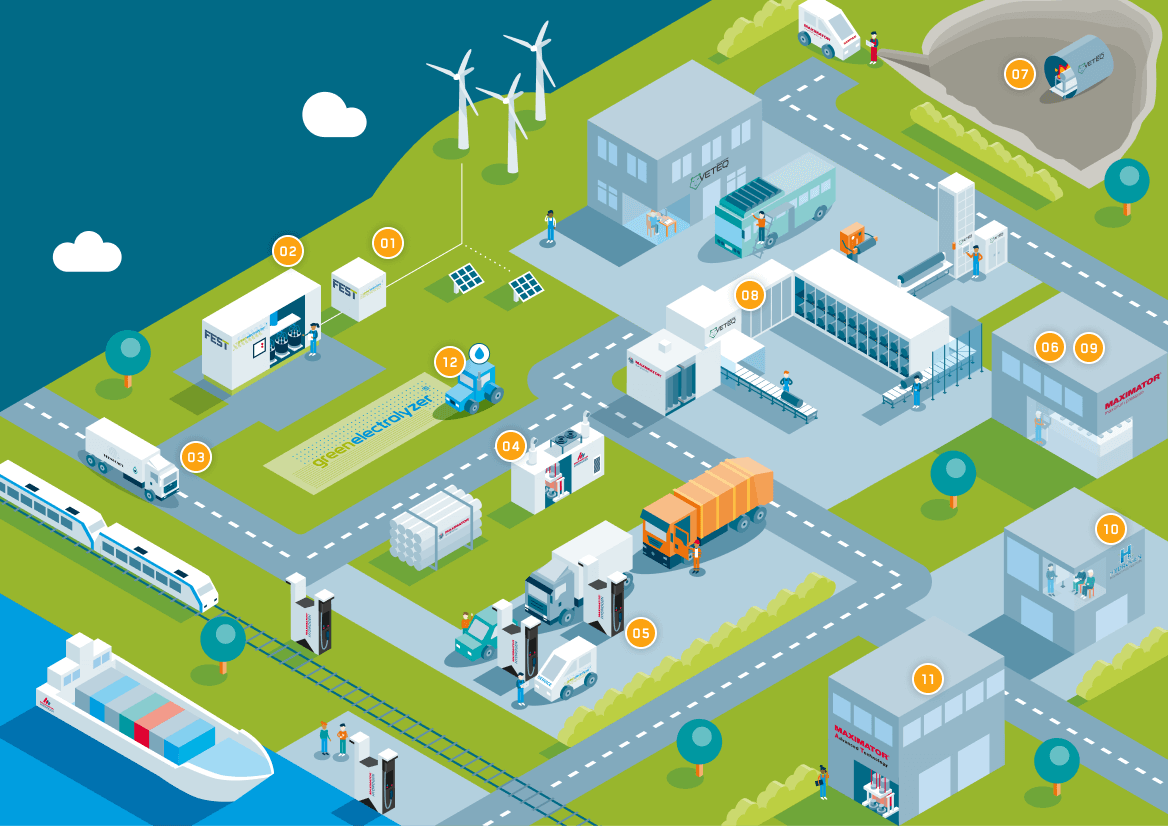

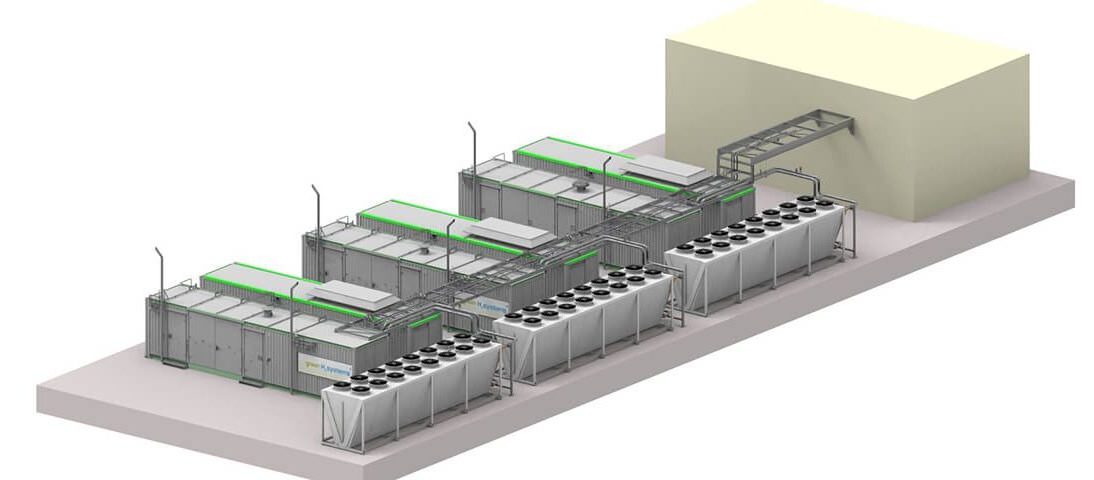

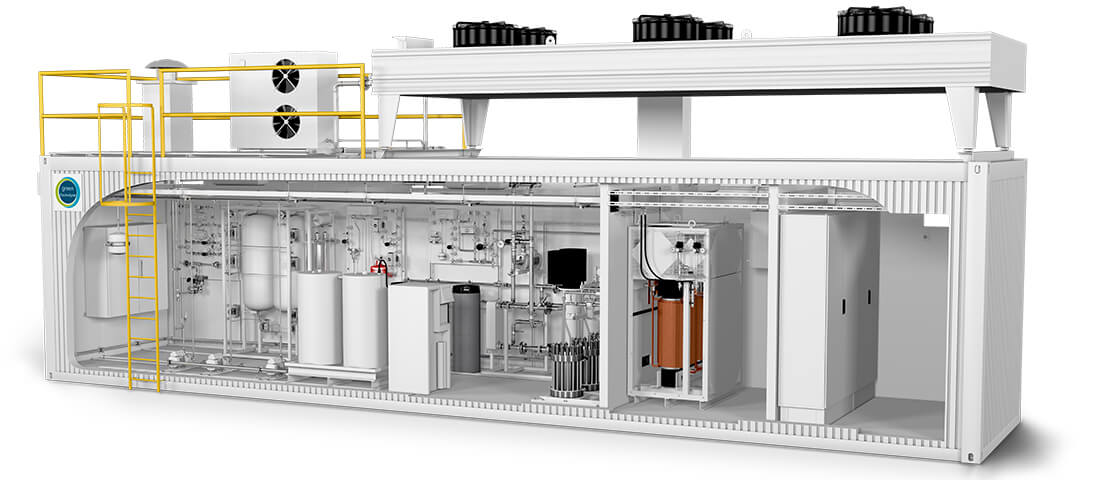

AVIA H2 Refueling Station

St. Gallen, Switzerland

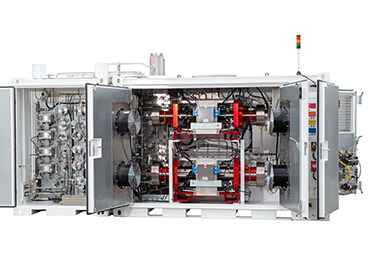

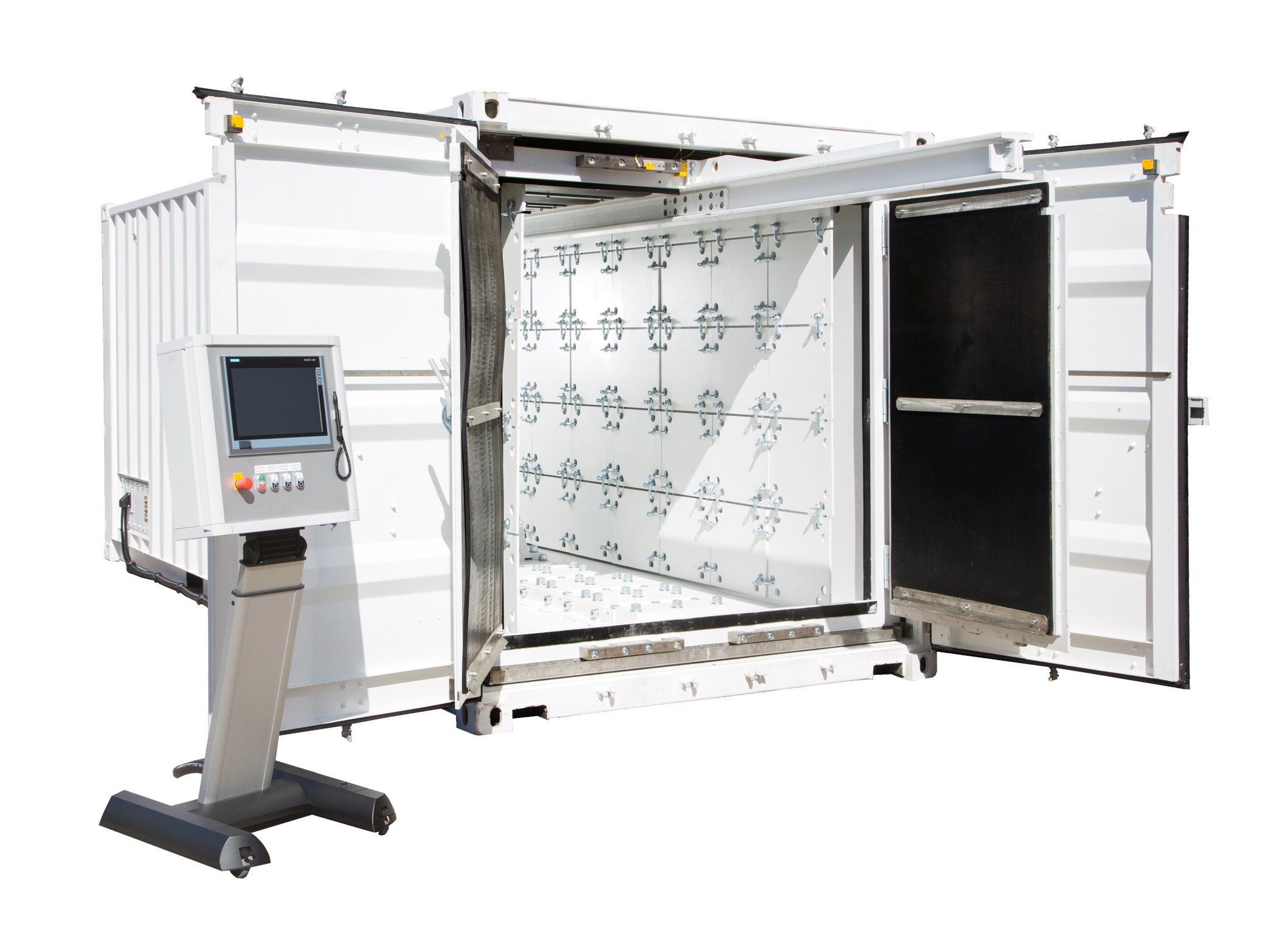

This first Swiss hydrogen filling station for buses has been in operation since 2020. Together with the Osterwalder Group, Maximator Hydrogen has already delivered 10 filling stations for the Swiss H2 filling station network, which primarily supply heavy-duty transport with hydrogen drives.